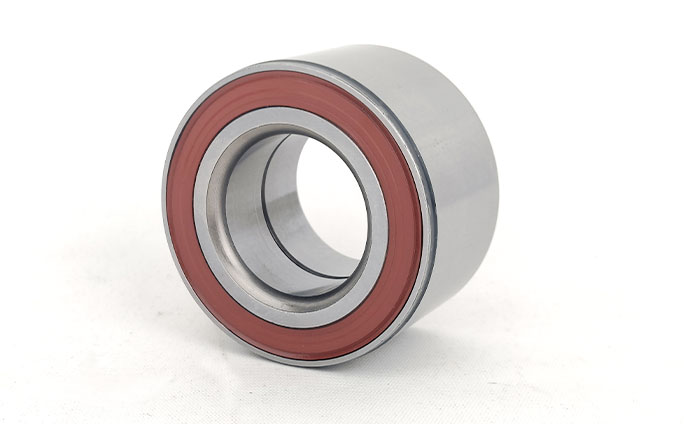

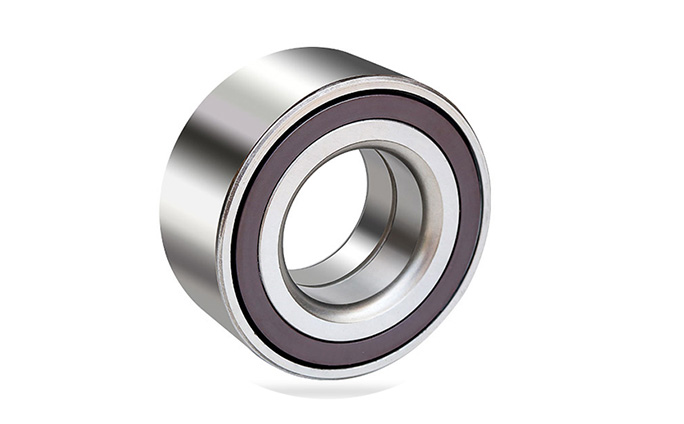

Automotive wheel hub bearings are critical components in vehicle suspension systems, used to support the wheels and ensure their smooth rotation. It connects the wheels and axles, bears the weight of the vehicle and the impact force from the road surface, while reducing friction and improving driving efficiency.

Product features:

High load-bearing capacity:

Using high-quality steel and precision manufacturing processes to ensure that bearings can withstand high loads and extreme working conditions.

Low friction design:

Optimized raceway and ball design to reduce friction losses and improve fuel efficiency.

Long service life:

After special heat treatment and surface treatment, the wear resistance and fatigue resistance are enhanced, and the service life is extended.

Excellent sealing performance:

Built in high-performance sealing rings effectively prevent dust, water, and impurities from entering, ensuring the cleanliness of the bearing interior.

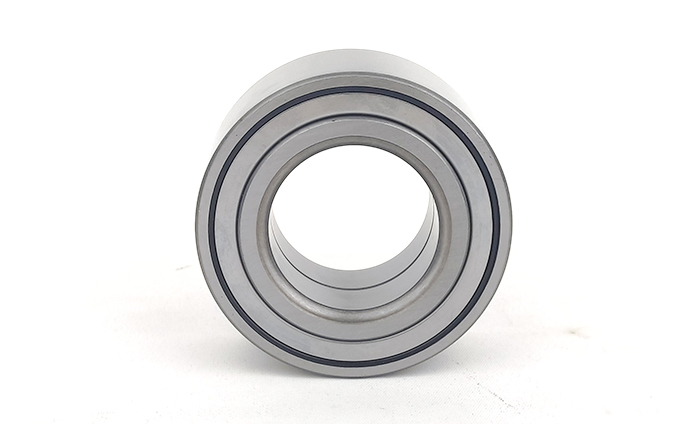

Easy installation:

Adopting an integrated design, reducing installation steps and lowering maintenance costs.

Wide applicability:

Suitable for various car models, including sedans SUV、 Trucks, etc.

Technical parameters:

Material: High carbon chromium steel (GCr15) or special alloy steel

Accuracy level: P5/P6 (high precision)

Sealing type: Contact or non-contact sealing

Lubrication method: Long term lubricating grease (excellent high and low temperature performance)

Working temperature range:- 40 ° C to+150 ° C

Bearing capacity: dynamic load XX kN, static load XX kN

Product advantages:

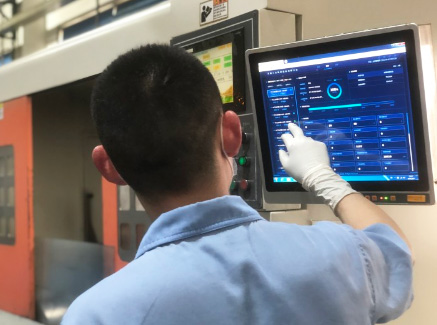

High reliability: After strict quality inspection and road testing, it ensures stable operation in various road conditions.

Energy saving and environmental protection: Low friction design reduces energy loss and meets the energy-saving requirements of modern automobiles.

Low maintenance cost: Integrated design and long-lasting grease reduce maintenance frequency and cost.

Application scenarios:

Passenger cars: sedans, SUVs, MPVs, etc.

Commercial vehicles: trucks, buses, construction vehicles, etc.

New energy vehicles: suitable for the special needs of electric and hybrid vehicles.

Installation and maintenance:

Installation precautions:

Ensure that the installation surface is clean and free of impurities.

Use specialized tools for installation to avoid knocking or improper operation.

Tighten the bolts according to the specified torque value.

Maintenance suggestion:

Regularly check if the sealing ring is intact.

Increase the frequency of inspections in harsh working conditions such as wading through water or muddy roads.

If any abnormal noise or vibration is found, replace the bearing in a timely manner.

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely.

NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely. ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.

ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.

Industry Accumulation in 8 Years

Industry Accumulation in 8 Years