The places where construction machinery is active are mostly mining sites in mountainous and desert areas that are far away from ordinary human life, sometimes even working 2000 meters underground. There are many types of such machinery, ranging from mineral crushing machinery to cutting machinery, screening machinery, loading machinery, conveying machinery, etc., all of which operate continuously 24 hours a day. Regardless of which type of machinery fails, it will have a significant impact on the production of the mining site. Moreover, due to the recent large-scale development of machinery, maintenance operations have become very difficult.

Therefore, in terms of the usage environment of bearings, there are many very demanding conditions for bearings, such as "heavy load+impact load", "light load+high-speed rotation", "heavy load+low-speed rotation", etc. Therefore, the bearings that users desire are products with robustness, durability, and high reliability that can resist these harsh working conditions.

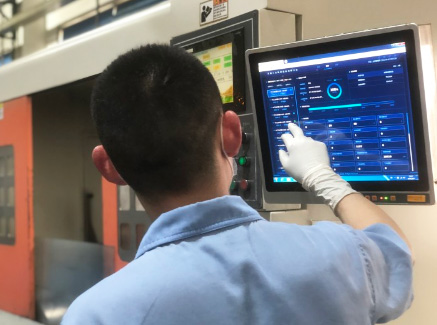

Construction machinery can work at low speeds, but reliable operation under concentrated pressure conditions is key to improving productivity and reducing downtime. Operators need to comply with strict environmental standards, control costs, and improve equipment performance. From wheel loaders to rollers, various types of machinery must work continuously and effectively under harsh conditions. Our expertise can help you achieve this goal, as components such as bearings, seals, and lubricants play a critical role in improving the performance of rotating equipment. Additionally, our intelligent lubrication system helps automate maintenance processes and save costs, while the condition monitoring system can detect early signals of component damage to prevent downtime.

The frequent start stop, polluted environment, and continuous vibration of construction machinery require high-performance products to meet these challenges and meet the needs of users. We supply various series of bearings and seals, whose improved functions can protect components from excessive wear. In addition, our expertise in lubrication also helps to extend the service life and maintenance interval of bearings.

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely.

NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely. ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.

ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.