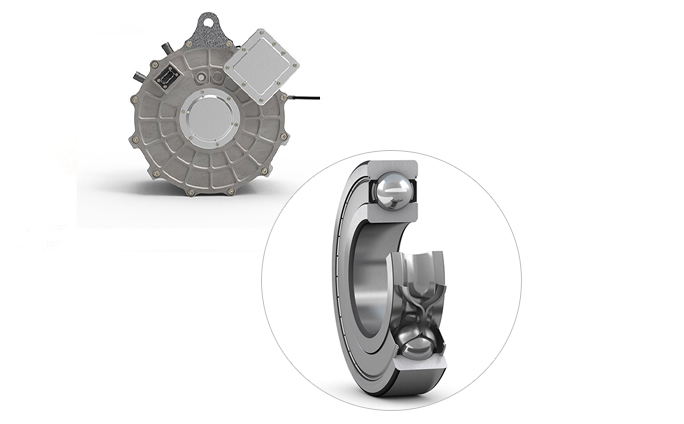

The supporting bearings for new energy vehicles are crucial components in automobiles.

Technical requirements:

High precision: In order to ensure the precise assembly and operation accuracy of automotive components, automotive supporting bearings usually need to have high dimensional accuracy and rotational accuracy to ensure the concentricity and perpendicularity of rotating parts, reduce vibration and noise.

High reliability: When driving in various complex road conditions and environments, bearings need to be able to maintain stable performance under long-term high loads, high-speed operation, as well as harsh temperature, humidity, and other conditions, with a long service life and low failure rate.

Low friction: Reducing the friction coefficient of bearings can improve the fuel economy of cars and reduce energy loss. Meanwhile, low friction can also lower the operating temperature of bearings and extend their service life.

Technical Parameter

Rated power (KW): 80

Rated speed (rpm): 1200

Rated torque (N.m): 636

Rated voltage AC (V): 380

Rated DC bus voltage DC (V): 540

Minimum bus voltage for full power operation (V): 400

Most efficient zone (%): ≥ 96.5%

High efficiency zone (%): ≥ 90.0%

Insulation level: H

Protection level: IP68

Working noise (dB): ≤ 80

Outer diameter size of water nozzle (mm): 25

Peak power (KW): 180

Peak speed (rpm): 3000

Peak torque (N.m): 1500

Rated current (Arms): 150

Maximum phase current (Arms): 380

Maximum speed corresponding to no-load back electromotive force (V): 710

Peak power duration (s): 60

Peak torque duration (s): 30

Motor dimensions (mm): φ 405 * 330

Weight (kg): ≤ 150

Cooling water inlet temperature (℃): ≤ sixty-five

Cooling water flow rate (L/min): ≥ 15.0

Working environment temperature (℃):- 40/+85

scope of application

8.5-meter bus with 600A main drive system

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely.

NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely. ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.

ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.

Industry Accumulation in 8 Years

Industry Accumulation in 8 Years