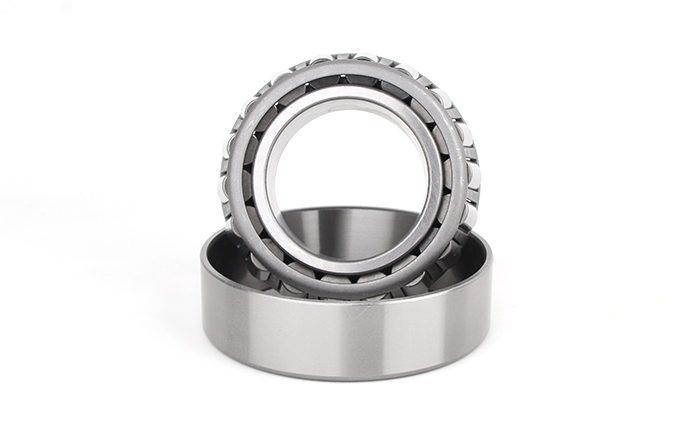

Structure Design

Inner and outer rings: Both have tapered raceways, and the taper of the inner and outer raceways matches each other to adapt to the rolling of tapered rollers. The inner and outer rings are usually made of high-strength alloy steel and undergo precision grinding and heat treatment processes to have high hardness and wear resistance.

Cone roller: It is the rolling element of a bearing, which is conical in shape. The size, quantity, and taper of the cone roller are designed according to the model and load-bearing requirements of the bearing. They are installed between the inner and outer rings and evenly distributed through a cage. The contact line between the cone roller and the raceway is straight, which can evenly distribute pressure and improve load-bearing capacity.

Retainer: Used to maintain the relative position of tapered rollers, so that they are evenly distributed during rolling, avoiding collisions or squeezing between rollers. Retainers are usually made of metal or polymer materials, with good wear resistance and toughness.

Working principle: Based on rolling friction, when the shaft is subjected to radial or axial loads, the tapered rollers roll between the inner and outer raceway to achieve force transmission and dispersion. Due to the smaller friction coefficient of rolling friction compared to sliding friction, it can reduce energy loss and improve the working efficiency of the bearing.

Performance characteristics

High load-bearing capacity: It can withstand large radial and axial loads, especially suitable for heavy-duty and high-speed working conditions of automobiles, such as engines, transmissions, driveshafts, and other parts.

Adjustable clearance: The clearance of a single row tapered roller bearing can be adjusted during installation by axially moving the outer or inner ring to generate end clearance (axial clearance) or preload force (axial interference) to meet different working requirements.

Good stability: The contact line between the tapered roller and the raceway is straight, the load distribution is uniform, the operation is smooth, the vibration and noise are reduced, and the stability and comfort of the car during driving can be guaranteed.

High reliability: High quality materials, advanced production processes, and good sealing performance enable tapered roller bearings to resist the invasion of impurities such as dust and moisture, and maintain reliable performance even in harsh working environments, extending their service life.

Application site

Transmission: Used to support the gear shaft of the transmission, withstand high-speed rotation and large torque, and ensure the correct meshing of gears and power transmission.

Differential: In the differential, tapered roller bearings can withstand the radial and axial loads of the differential gears, enabling the differential to operate normally and achieve different speeds of the left and right wheels.

Wheel hub: Conical roller bearings are often used in the front and rear wheel hubs of automobiles to withstand the weight of the vehicle and various impacts during driving, ensuring stable rotation of the wheels and safe driving of the vehicle.

Drive shaft: The drive shaft connects the gearbox and the drive wheels, and tapered roller bearings are used to support the drive shaft, bearing the radial and axial loads generated when the drive shaft transmits power, ensuring smooth rotation of the drive shaft.

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely.

NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely. ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.

ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.

Industry Accumulation in 8 Years

Industry Accumulation in 8 Years