The main reason for the high operating temperature of rolling bearings is that the internal clearance of the bearings is too small or the design and manufacturing accuracy of the components is poor. In order to facilitate the installation of fan equipment; Dismantling, repairing, and maintaining Generally, tight fitting sleeve bearings with tapered holes and inner rings are used in the design of bearing seats. However, problems can also occur due to negligence in installation procedures, especially in adjusting the appropriate clearance.

Methods for detecting and troubleshooting faults in rolling bearings:

(1) Inherent noise:

Rolling track sound and various bearing and rolling friction sounds are inherent sounds of rolling bearings. Rolling track sound is generated by the elastic characteristics of rolling elements in contact with the rolling track. When the rolling bearing rotates, the rolling elements roll on the rolling track and emit a continuous and sophisticated sound; Abnormal rolling friction sound can produce uncomfortable metal friction abnormal sounds such as "creak, creak", which will not be produced when smooth and good So it's not a problem under normal circumstances, as long as the noise increases, attention should be paid.

(2) Noise related to bearing manufacturing: This includes sticking frame noise and vibrato. Sticking frame noise mainly occurs in ball bearings and bearings. When rolling bearings rotate, sound is emitted due to the vibration of the sticking frame and the impact between the sticking frame and the rolling elements. This kind of sound has periodicity, and vibrato (various bearings) is a sound with a certain frequency, which is caused by the vibration caused by the large waviness on the raceway surface. This phenomenon is a common problem, and we need to pay more attention in the future.

(3) Noise caused by improper use: It exists in all types of bearings When the outer surface of the rolling bearing raceway or rolling element is damaged, dented, or corroded, a certain period of noise and vibration will be generated When dust invades the bearing during operation, it will produce dirt noise. This type of noise is non periodic and also accompanied by vibration. Its sound intensity is not fixed and varies from time to time.

(4) When handling, remove the tightening sleeve and readjust the fit tightness between the shaft and the inner ring. After replacing the bearing, the clearance should be taken as 0.10mm. After reinstallation, restart the fan, and the bearing vibration value and operating temperature have returned to normal.

The internal clearance of the bearing is too small Rapid increase in operating temperature: The inner ring taper hole of the bearing is too loose with the tightening sleeve, and the bearing is prone to failure and burnout in the short term due to loose mating surfaces. As for large bearings, sometimes in order to avoid installation and disassembly difficulties, the method of fitting the clearance between the rings that bear rotational loads is also used. In this case, the shaft should be made of hard materials, with a carefully machined surface and sufficient lubricant added to prevent damage caused by slipping to the greatest extent possible.

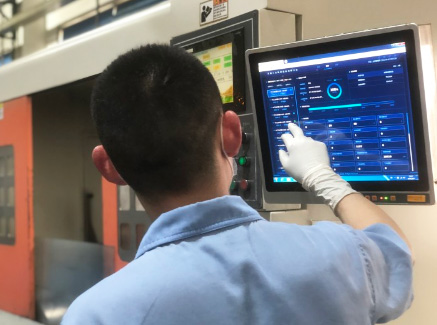

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely.

NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely. ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.

ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.