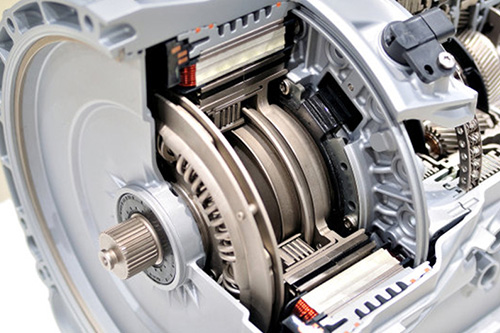

The unique variable contact design of the clutch release bearing seal allows for high speed, wear resistance, long service life under high loads, and minimizes noise and vibration. The clutch release bearing also has a unique sealing system that isolates pollutants while retaining lubricating grease.

Feature 1:

1. Provide multiple installation solutions for two bearing rings by rolling the outer ring;

2. Specially formulated elastic materials according to the speed and temperature requirements of the application;

3. Throughout the entire life of the bearing, it has excellent grease retention, reduced friction, and excellent wear resistance;

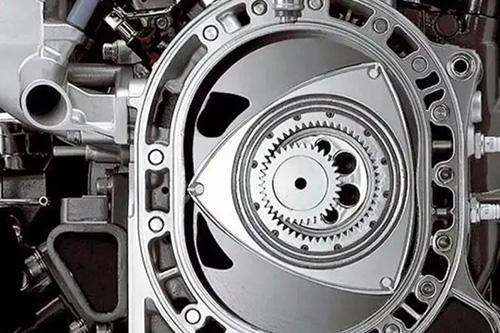

The lip seal adopts advanced materials and sealing lip design to provide lower friction and good drainage function, thereby extending its service life. Magnetic trigger wheels can be integrated into the sealing system to provide signals for the anti lock braking system.

Feature 2:

1. Independent axial dust lip;

2. Radial sealing lip and grease lip;

3. Traditional sealing lip configuration;

4. Using stainless steel oil slinger as the sealing surface for operation;

5. Elastic materials optimized for friction;

6. Low friction to reduce power loss and carbon dioxide emissions;

7. Achieve longer service life of bearings with superior dirt and grease removal capabilities

The main advantage of the main pin seal is that it can eliminate the frequent lubrication usually required for the steering shaft main pin. Another advantage of the sensor is that it may be used in modern steering systems, which typically do not retain the lubricating grease that has been added.

Feature Three:

1. Multiple sealing lip designs, such as double lip and single lip, provide excellent grease retention throughout the entire bearing life;

2. Lining with rubber seals and ring gaskets for assembly;

3. Specially configured sealing lip with PTFE coating on its surface;

4. Special assembly functions suitable for different customers and service requirements, easy installation and disassembly during maintenance process;

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely.

NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely. ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.

ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.