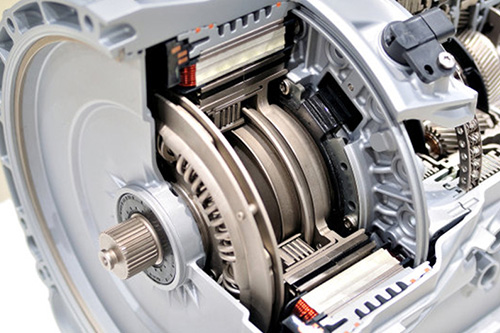

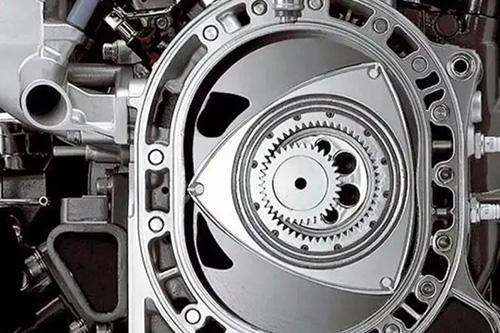

The main function of wheel hub bearings is to bear weight and provide precise guidance for the rotation of the wheel hub. It bears both axial and radial loads and is a very important component. Traditional car wheel bearings are composed of two sets of tapered roller bearings or ball bearings, and the installation, oiling, sealing, and clearance adjustment of the bearings are all carried out on the car production line. This structure makes it difficult to assemble, costly, and unreliable in automobile production plants. Additionally, during maintenance at repair points, the bearings need to be cleaned, oiled, and adjusted. The wheel hub bearing unit is developed on the basis of standard angular contact ball bearings and tapered roller bearings. It integrates two sets of bearings and has the advantages of good assembly performance, eliminating clearance adjustment, light weight, compact structure, large load capacity, pre installation of lubricating grease for sealed bearings, omitting external wheel hub seals, and avoiding maintenance. It has been widely used in cars and has a trend of gradually expanding its application in heavy-duty vehicles.

When one of the four wheel hub bearings of the vehicle is damaged, you will hear a continuous buzzing sound inside the car while driving. It is unclear where this sound comes from, and it feels like the entire cabin is filled with this buzzing sound, and the faster the vehicle speed, the louder the sound. Here is the method of judgment:

1. Open the car window and listen for the sound coming from outside the car;

2. After increasing the speed (when there is a loud buzzing sound), shift the gear to neutral and let the vehicle slide. Observe if the noise comes from the engine. If the buzzing sound does not change when sliding in neutral, it is likely due to a problem with the wheel bearings;

3. Stop temporarily, get off the car and check if the temperature of the wheel axle is normal. Use your hand to touch each of the four wheel hubs and roughly feel if their temperatures are consistent (when the brake shoe and pad clearance are normal, there is a temperature difference between the front and rear wheels, and the front wheel should be higher). If the difference is not significant, continue driving slowly to the repair station;

4. Lift the car with an elevator (previously release the handbrake and shift to neutral). Without an elevator, you can use a jack to lift each wheel one by one, and manually rotate each of the four wheels quickly. When encountering a problematic axle, it will make a sound, which is completely different from other axles. With this method, it is easy to distinguish which axle has a problem.

If the wheel hub bearing is severely damaged with cracks, pitting, or erosion, it must be replaced. Before installing a new bearing, apply lubricating grease first, and then reinstall it in reverse order. The replaced bearing must rotate flexibly without any impurities or vibrations.

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely.

NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely. ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.

ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.