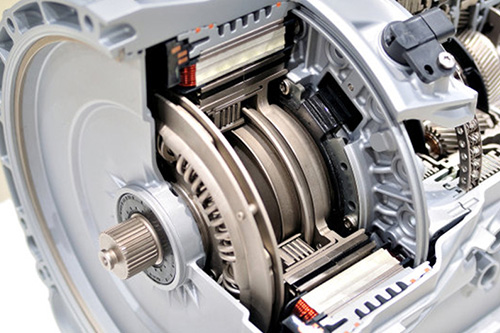

In the past, the wheel hub bearings of sedans were mostly paired with single row tapered rollers or ball bearings. With the development of technology, sedan wheel hub units have been widely used in cars. The scope and usage of wheel hub bearing units are increasing day by day, and have now developed to the third generation: the first generation is composed of double row angular contact bearings. The second generation has a flange on the outer raceway for fixing the bearing, which can be easily fitted onto the axle and fixed with nuts. Make car maintenance easier. The third-generation wheel hub bearing unit adopts a combination of bearing unit and anti lock braking system ABS. The wheel hub unit is designed with an inner flange and an outer flange. The inner flange is fixed to the drive shaft with bolts, while the outer flange installs the entire bearing together. Worn or damaged wheel hub bearings or wheel hub units can cause inappropriate and costly failures of your vehicle while driving, and even pose a threat to your safety. Please pay attention to the following matters in the use and installation of wheel hub bearings:

1. To ensure maximum safety and reliability, it is recommended that you regularly check the wheel hub bearings regardless of the age of the vehicle - paying attention to early warning signals of bearing wear, including any friction noise during rotation or abnormal deceleration of the suspension combination wheels during turning. For rear wheel drive vehicles, it is recommended to lubricate the front wheel hub bearings when the vehicle has traveled 38000 kilometers. When replacing the brake system, check the bearings and replace the oil seal.

2. If you hear noise coming from the hub bearing area, the first thing is to identify the location where the noise is occurring. There are many moving parts that may produce noise, and it is also possible that some rotating parts have come into contact with non rotating parts. If it is confirmed that the noise is from the bearing, the bearing may be damaged and needs to be replaced.

3. Because the working conditions for bearing failure on both sides caused by the front wheel hub are similar, even if only one bearing is damaged, it is recommended to replace it in pairs.

4. Wheel hub bearings are sensitive and require the correct method and appropriate tools in any situation. During storage, transportation, and installation, the components of the bearings must not be damaged. Some bearings require significant pressure to be pressed in, so specialized tools are needed. Be sure to refer to the car manufacturing manual.

5. When installing bearings, they should be installed in a clean and tidy environment. Small particles entering the bearings can also shorten their service life. It is very important to maintain a clean environment when replacing bearings. Do not use a hammer to strike the bearing, and be careful not to drop the bearing on the ground (or handle it improperly). Before installation, the condition of the shaft and bearing seat should also be checked, as even minor wear can lead to poor fit and early failure of the bearings.

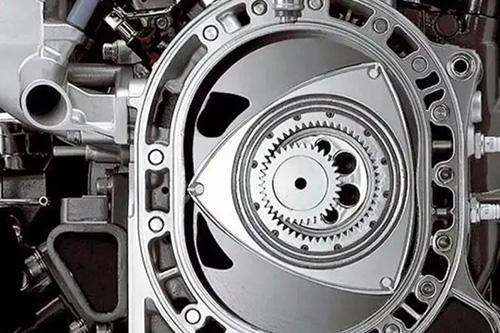

6. Do not attempt to disassemble the hub bearing unit or adjust the sealing ring of the hub unit, as this may damage the sealing ring and allow water or dust to enter. Even the sealing ring and the raceway of the inner ring are damaged, causing permanent failure of the bearing.

7. There is a magnetic thrust ring inside the sealing ring of the bearing equipped with ABS device, which cannot be subjected to collision, impact or collision with other magnetic fields. Before installation, remove them from the packaging box and keep them away from magnetic fields, such as electric motors or power tools used. When installing these bearings, observe the ABS warning needle on the dashboard through road condition testing to change the operation of the bearings.

8. A wheel hub bearing equipped with an ABS magnetic thrust ring can be used to determine which side the thrust ring is installed on. A lightweight object can be placed near the edge of the bearing, and the magnetic force generated by the bearing will attract it. During installation, point the side with magnetic thrust ring inward, facing the sensitive component of ABS. Attention: Incorrect installation may cause the brake system to malfunction.

9. Many bearings are sealed and do not require lubrication throughout their entire lifespan. Other unsealed bearings, such as double row tapered roller bearings, must be lubricated with grease during installation. Due to the different sizes of the inner cavities of bearings, it is difficult to determine how much grease to add. It is important to ensure that there is grease in the bearings. If there is too much grease, excess grease will seep out when the bearings rotate. General experience: During installation, the total amount of grease should account for 50% of the clearance between the bearings.

10. When installing the locking nut, the torque varies greatly due to the different types of bearings and bearing seats. Please refer to the relevant instructions.

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely.

NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely. ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.

ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.