The comprehensive indicator of the intrinsic quality of bearing steel is fatigue life. Some scholars have proposed that reducing oxygen content has not yet significantly improved the fatigue life of bearing steel. In fact, only by simultaneously reducing the content of oxides and sulfides can we fully tap into the potential of the material and significantly improve the fatigue life of bearing steel. Why does reducing oxygen content not improve the fatigue life of bearing steel? Reason for sharing: After the reduction of oxide inclusions, excess sulfides become unfavorable factors affecting the fatigue life of steel. Only by simultaneously reducing the content of oxides and sulfides can we fully tap into the material's potential and significantly improve the fatigue life of bearing steel.

What factors affect the fatigue life of bearing steel?

1. The influence of nitrides on fatigue life

Some scholars have pointed out that increasing nitrogen in steel leads to a decrease in the volume fraction of nitrides, which is due to the reduction in the average size of inclusions in the steel. Due to technological limitations, there are still a considerable number of inclusion particles smaller than 0.2 inches that have not been included. It is precisely the presence of these tiny nitride particles that directly affects the fatigue life of bearing steel. Ti is one of the strongest elements in the formation of nitrides, with a small specific gravity, easy to float, and a portion of Ti remaining in the steel to form angular inclusions. This type of inclusion is prone to causing local stress concentration and fatigue cracking, so it is necessary to control the generation of such inclusions.

The experimental results showed that the oxygen content in the steel decreased to below 20ppm, the nitrogen content increased, the size, type, and distribution of non-metallic inclusions were improved, and stable inclusions were significantly reduced. Although the number of nitride particles in steel increases, they are very small and distributed in a dispersed state at grain boundaries or within the crystal, which becomes a favorable factor, resulting in a good combination of strength and toughness of bearing steel. This greatly increases the hardness and strength of the steel, especially the effect of improving contact fatigue life, which is objectively present.

2. The influence of oxides on fatigue life

The oxygen content in steel is an important factor affecting the material. The lower the oxygen content, the higher the purity and the corresponding rated life. There is a close relationship between oxygen content and oxides in steel. During the solidification process of molten steel, oxygen dissolved from elements such as aluminum, calcium, and silicon forms oxides. The content of oxide inclusions is a function of oxygen. As the oxygen content decreases, oxide inclusions will decrease; The nitrogen content, like the oxygen content, also has a functional relationship with nitrides. However, due to the dispersed distribution of oxides in steel, they play a supporting role similar to carbides, so they do not have a destructive effect on the fatigue life of steel.

Steel, due to the presence of oxides, damages the continuity of the metal matrix, and because the expansion coefficient of oxides is smaller than that of bearing steel matrix, it is prone to stress concentration when subjected to alternating stress, becoming the source of metal fatigue. Stress concentration mostly occurs between oxides, point like inclusions, and the matrix. When the stress reaches a sufficient level, cracks occur and rapidly propagate, leading to failure. The lower the plasticity and sharper the shape of inclusions, the greater the stress concentration.

3. The influence of sulfides on fatigue life

The sulfur content in steel is almost entirely in the form of sulfides. As the sulfur content in steel increases, the sulfides in the steel also increase accordingly. However, because sulfides can effectively surround oxides, reducing the impact of oxides on fatigue life, the number of inclusions does not necessarily affect fatigue life, but is related to the properties, size, and distribution of inclusions. The more certain impurities there are, the lower the fatigue life must be, and other influencing factors must be comprehensively considered. Sulfides are dispersed in small particles in bearing steel and mixed with oxide inclusions, making it difficult to identify even using metallographic methods. Experimental results have shown that increasing the amount of Al on the basis of the original process has a positive effect on reducing oxides and sulfides. This is because Ca has a strong desulfurization ability. Inclusions have little effect on strength, but pose a greater threat to the toughness of steel, and their degree of harm depends on the strength of the steel.

The fracture process of GCr15 steel is mainly characterized by cleavage and quasi cleavage fracture mechanisms according to fracture analysis. Expert Xiao Jimei pointed out that inclusions in steel are a brittle phase, and the higher the volume fraction, the lower the toughness; The larger the size of the inclusions, the faster the decrease in toughness. For the toughness of cleavage fracture, the smaller the size of inclusions and the smaller the spacing between inclusions, the toughness not only does not decrease, but also increases. If the arrangement of brittle phases in the crystal is denser, the distance between dislocation plugs can be shortened, making cleavage fracture less likely to occur and thus improving the strength of cleavage fracture. Someone has conducted a special experiment: A and B batches of steel belong to the same steel type, but their inclusion levels are different.

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services

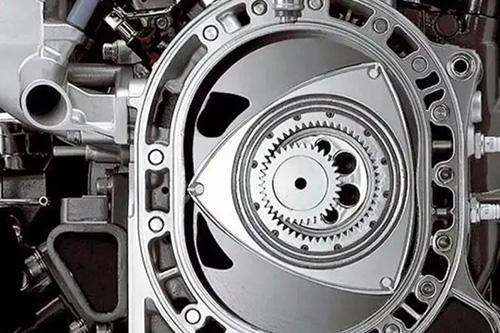

AboutThe business philosophy of "manufacturing with heart and providing sincere service" aims to repay new and old customers with exquisite technology, high-quality products, and perfect services NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely.

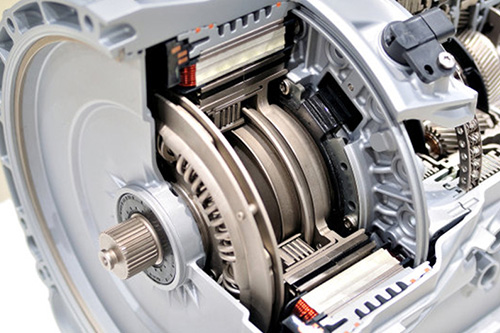

NewsElaborated development of high performance hub unit bearing, innovative design, excellent process and high-quality material selection help the vehicle drive safely. ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.

ProductThe high-performance wheel hub unit bearings integrate advanced design and high-quality materials, injecting strong power into the safe driving of automobiles.